How our green waste is keeping patients warm

With all the focus on climate change and sustainability, we thought it would be timely to share a scheme that we’ve been involved in for the last 25 years – a classic example of a zero waste economy.

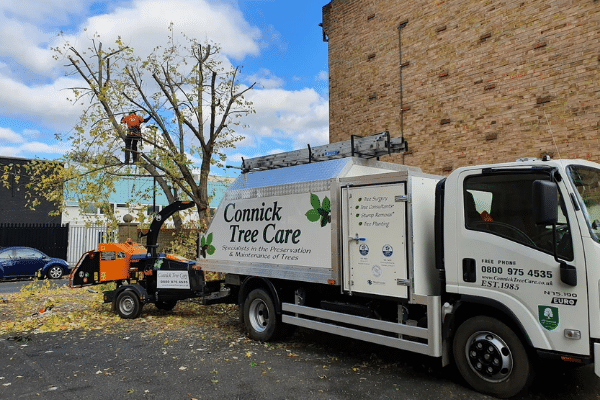

Mike Connick, MD of Connick Tree Care, has spent his working life promoting trees and their environmental benefits. He says, “I’ve always been proud to be working in a business that is ‘green’ to the core”. And it goes a lot further than just preserving the health of trees, which themselves play a crucial role in absorbing CO2 out of the atmosphere.

A significant part of our work is pruning and felling trees and that creates a lot of timber and wood chip. In years gone by, this was regarded as low-value waste. The logs would be burned in the yard – not good for the environment – and the woodchip would go to be used was mulch for gardens. These days, however, it serves as a non-polluting fuel to heat local amenities, including schools and a hospital.

Connick Tree Care supplies about six 25 ton lorry loads of woodchip a month to the biomass network, including Pembury Hospital, near Tunbridge Wells in Kent. There it is hooked up to an automated system that feeds the wood chip into a special boiler, which efficiently burns the wood chip to create hot water, used to heat the hospital.

Mike Connick advised on the design and implementation of this heating system. Mike says, “A condition of the planning consent was that 10% of the energy required (3 million kWh) came from a renewable source. The installed biomass boiler produces this amount and reduces carbon emissions by 471,000kg per month.”

Woodchip is a very efficient biofuel. It is easy to transport and can be fed automatically into the boiler using an auger. Fresh woodchip heats up very quickly and moisture naturally evaporates. Having been pre dried, the boiler executes a final dry before combustion to totally minimise the moisture content, which makes for a cleaner burn and less polluting gas emissions. Any particulates are filtered out of the emissions to prevent air pollution.

Here’s the full process of fuelling Pembury Hospital with energy from green waste.

We take our responsibility to the environment and climate change very seriously. We are deploying more and more battery-powered tools and the biofuel boiler that we supply at Pembury Hospital is much more eco-friendly than an oil or gas fired boiler.

So at one end of the process we are encouraging trees and the absorption of CO2, at the other end we are helping to reduce the use of fossil fuels and the CO2 that they emit into the atmosphere.

If you would like more information about Connick Tree Care and our environmentally friendly services, send us a message or call 01737 779191.